Matteo Anthony Aiello

Interactive resume and portfolio.

Profile

Engineer at Tesla, web developer, athlete, and liver of life.

About Me:

I am currently working as a full-time Battery Manufacturing Engineer at Tesla. I studied Mechanical Engineering at The University of Victoria and specialized in Energy Systems. I've also spent plenty of time diversifying my skillset through programming classes and projects. I grew up in Calgary, AB but have had many homes in and around the country throughout the years.

Biography:

Name:

Matteo Aiello

Age:

24 years old

Current Location:

Palo Alto, CA

Post-Secondary:

BEng - Bachelor of Engineering with Distinction (University of Victoria)

I programmed this website from scratch in my free time using HTML, CSS, and JavaScript. It was programmed in Visual Studio Code, and is hosted by Github Pages. You can click here to see my repository.

Git hub

Projects

Exploring my own creativity has always been important to me. My education has afforded me new opportunities to do so and I do not take that for granted. Take a look at some of my work throughout university...

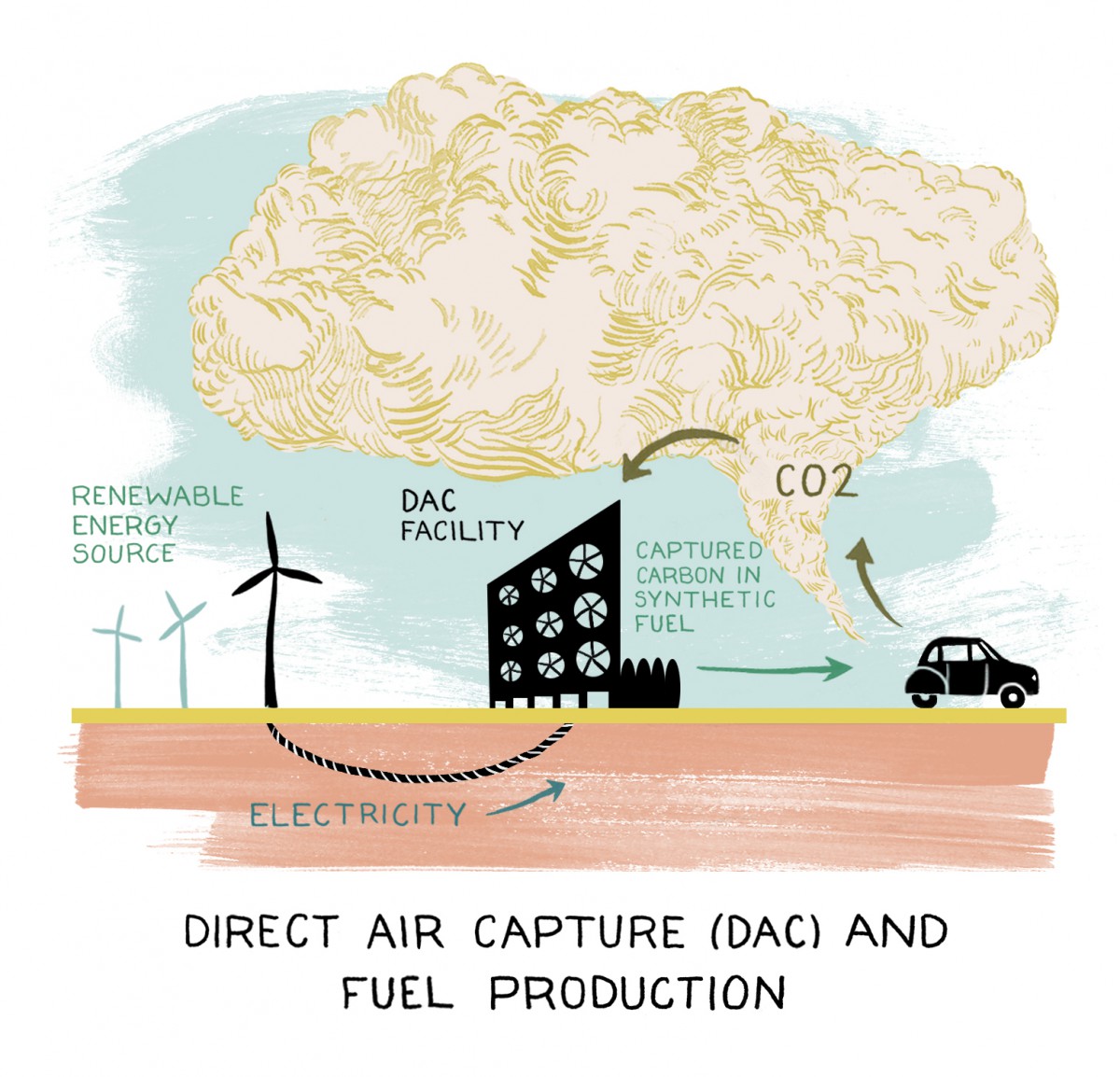

DAC Research

Direct Air Capture (DAC), technology of the future.

Skills:

Technical Writing, Research, Data Management

Turbine Gearbox Design

Tides are more predictable than the wind or sun.

Skills:

Stress/Fatigue Calculations, CAD, Gearing, Technical Writing, Communications

Energy-Harvesting

Solution

Because cable management is tedious.

Skills:

Machining, CAD, 3D Printing, Assembly, Electronics, Soldering

Optical Calibration Device

Image recognition works better with reliable data.

Skills:

CAD, Machining, Mechatronics

Note: this section is usually under construction or outdated. For more current information about my personal projects and experience, check out my resume

Curriculum Vitae

Dive in to my personal and professional experiences.

EDUCATION:

_______

University of Victoria

Sept. 2017 - Aug. 2022

Bachelor of Engineering (BEng) - Mechanical Engineering with Distinction

During my time at university, I specialized in the study of energy systems, and completed 5 different internships with 5 different companies. The faculty of engineering has been a great asset in my discovery and practice of calculus, mechanics, design, technical writing, teamwork and more.

Victoria, BCCAREER EXPERIENCE:

_______

Tesla Motors Inc.

Nov. 2022 - Current

Battery Manufacturing Engineer

Working as part of the Manufacturing Process Development Team on battery packing joining processes. The team specializes in joining technologies like Self-Pierce Rivets, Flow Drill Screws, Potting, Sealants, Fasteners, and more.

Palo Alto, CA | tesla.comTesla Motors Inc.

Jan. 2022 - May 2022

Battery Manufacturing Engineer (Co-op)

Worked as part of the Battery Manufacturing Process Development Team with focus on the Model Y Structural Battery, implementing and validating design for manufacturing, process optimization, and battery joining methods Operated, programmed, and maintained 6-axis (Fanuc) robots for manufacturing and product development, employing strict safety protocol and engineering practices. Designed and assembled test jigs and development tools to support battery manufacturing and design. Acted as a primary point of contact for battery teardown R&D, implementing and supporting smart data collection methodology, coordinating/delegating work, and collating technical data.

Fremont, CA | tesla.comGeneral Fusion Inc.

May 2021 - Sep. 2021

Mechanical Engineer (Co-op)

Worked on testing and optimizing the team’s primary compression test bed: the Cylindrical Water Compressor (CWC). The CWC simulates shaped collapses for plasma compression in a nuclear fusion reactor using pneumatics. CWC-related tasks included pneumatic design/assembly, 3D modelling, Python scripting for pressure analysis, automation in LabVIEW, 3D printing (SLA), diagnostic equipment calibration, development, and assembly. Underwent thorough design of a custom calibration device to mitigate error in image-recognition algorithms. Conducted design reviews of 3D models, machined custom parts, and assembled the apparatus. Operated a high-pressure vessel with high-powered, red/infrared, collimated lasers from an integrated control panel. Created various test jigs for simulation of certain events/behaviors related to optics and pneumatics.

Burnaby, BC | generalfusion.comErgonomyx Technologies Inc.

May 2020 - Sep. 2020

Mechanical Engineer (Co-op)

Conducted hardware/mechanical design and assembly using 3D CAD models, 2D drafts, and physical prototyping. Handled physical assembly, changes and adaptive technology with the current version of stand up desks and under desk bikes. Practiced safe machining and mechanical tool skills (lathe, mill, welding, grinder, CNC mill, among others) and 3D printing using FDM technology with materials such as PLA, TPU, SLA. Standardized CAD drawings and processes.

Victoria, BC | ergonomyx.comCorvus Energy Ltd.

Jan. 2019 - May 2019

Systems Manufacturing Engineer (Co-op)

This position offered the opportunity to work with integrated systems. I built and modelled a thermocycling test jig to simulate stress/strain on a lithium-ion battery module due to thermal expansion differentials. I developed python scripts to evaluate resistance data from a DAQ in MATLAB. I operated machining tools to complete various tasks (lathe, mill, drill press, etc.). I used Solidworks CAD to model and design battery modules with FEA to address stress cracks on laser-welds. I used LabView and MATLAB to create a standardized vibration-testing method for electrical components experiencing shipboard vibrations.

Richmond, BC | corvusenergy.comCrescent Point Energy Corp.

May 2018 - Sept. 2018

Mechanical Engineer (Co-op)

Assisted with and provided research for multiple projects with aim to reduce company carbon intensity (emissions/production). Focused primarily on solar, wind energy and power reduction. I performed economic modelling, emissions projections, power savings estimates, and CAD layouts to help assess the feasibility of new projects. I became familiar with and competent assessing PFDs, P&IDs, and other schematics using Microsoft Vizio. I was even able to utilize the laws of fluid mechanics and thermodynamics to make calculated projections for heat exchangers in CPG production territories.

Calgary, AB | crescentpointenergy.comEdgetech Computing Inc.

May 2020 - Current

Web Development / IT Support Consultant

Occasionally providing front-end, back-end support to Edgetech clients in need of ongoing/periodic maintenance and optimization of their sites. Offering the

creative, professional development needed by clients in pursuit of a flawless user/customer interface. Currently using HTML, CSS, JavaScript, and WordPress

with SSL protocol management.

Note: Work in this field is a means of secondary income and personal enjoyment.

Solaires Enterprises Inc.

Aug. 2020 - Apr. 2021

UX/UI Development Team Lead

Primarily designing front-end prototypes for website and mobile application using InVision Studio and Sketch. Coordinating team communications and workflow, organizing data and media assets, and

assisting programmers throughout development.

Note: Work in this field is a means of secondary income and personal enjoyment.

Qualifications

Find out what's in my toolbox.

Software

- Solidworks CAD/Simulation (Proficient)

- Fusion360 CAD/Simulation (Proficient)

- Siemens NX CAD (Competent)

- Catia V5/6 (Competent)

- AutoCAD (Beginner)

- PLC Programming (Competent)

- Microsoft Excel (Proficient)

- GitHub/GitLab (Proficient)

- LabView (Competent)

- MySQL (Beginner)

- MATLAB (Proficient)

- C Programming (Competent)

- Python Programming (Competent)

- HTML (Proficient)

- CSS (Proficient)

- Bootstrap Framework (Competent)

- JavaScript (Beginner)

- SSL Protocol (Competent)

- CircuitLab (Competent)

- ANSYS (Beginner)

Hardware

- 3D Printing (PLA,TPU,SLA) (Proficient)

- Machining - Lathe (Competent)

- Machining - Mill (Competent)

- Machining - Miscellaneous (Proficient)

- Pneumatics (fittings, seals, o-rings, etc.) (Competent)

- Engineering Drawings (Proficient)

- Dimensioning/Tolerancing (GD&T) (Proficient)

- Linear Circuitry (Competent)

- Soldering (Competent)

- CNC Operation (Beginner)

Contact

Don't hesitate to reach out with any inquiries or feedback.